Edit Content

Address

Department of Materials Engineering, Indian Institute of Science Bangalore, Bangalore - 560012, India

Department of Materials Engineering, Indian Institute of Science Bangalore, Bangalore - 560012, India

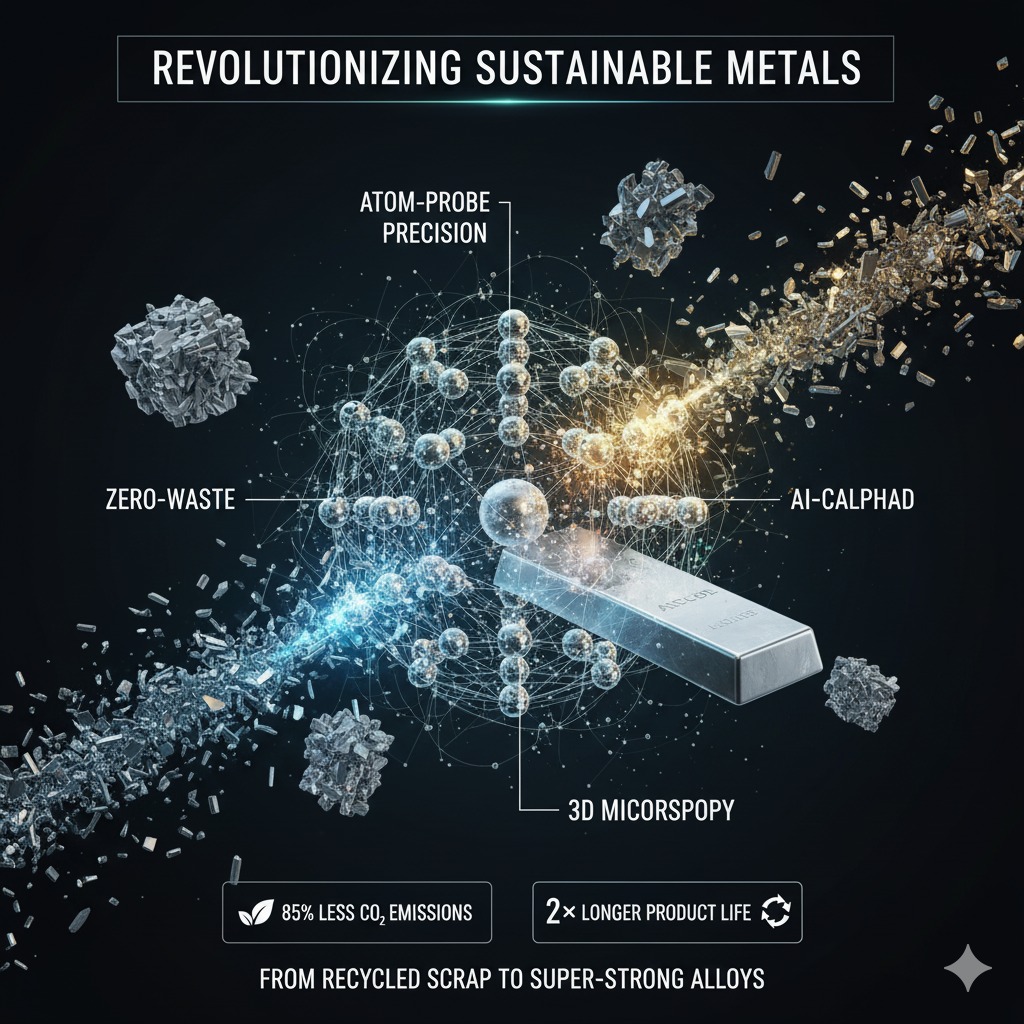

We turn fundamental alloy physics into real-world performance — from creep-resistant Ni-blades to ultra-light Al-Mg EV components — cutting CO₂ by up to 85% while doubling component life.

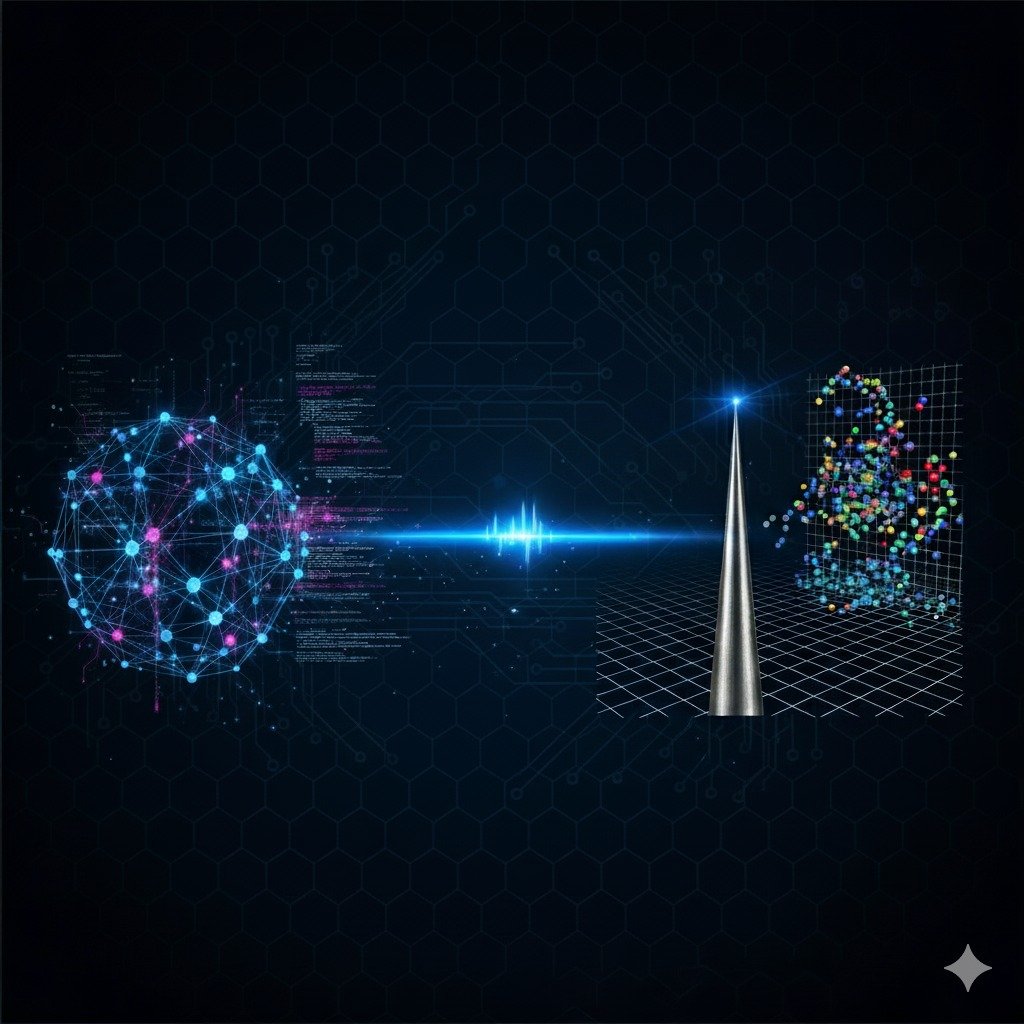

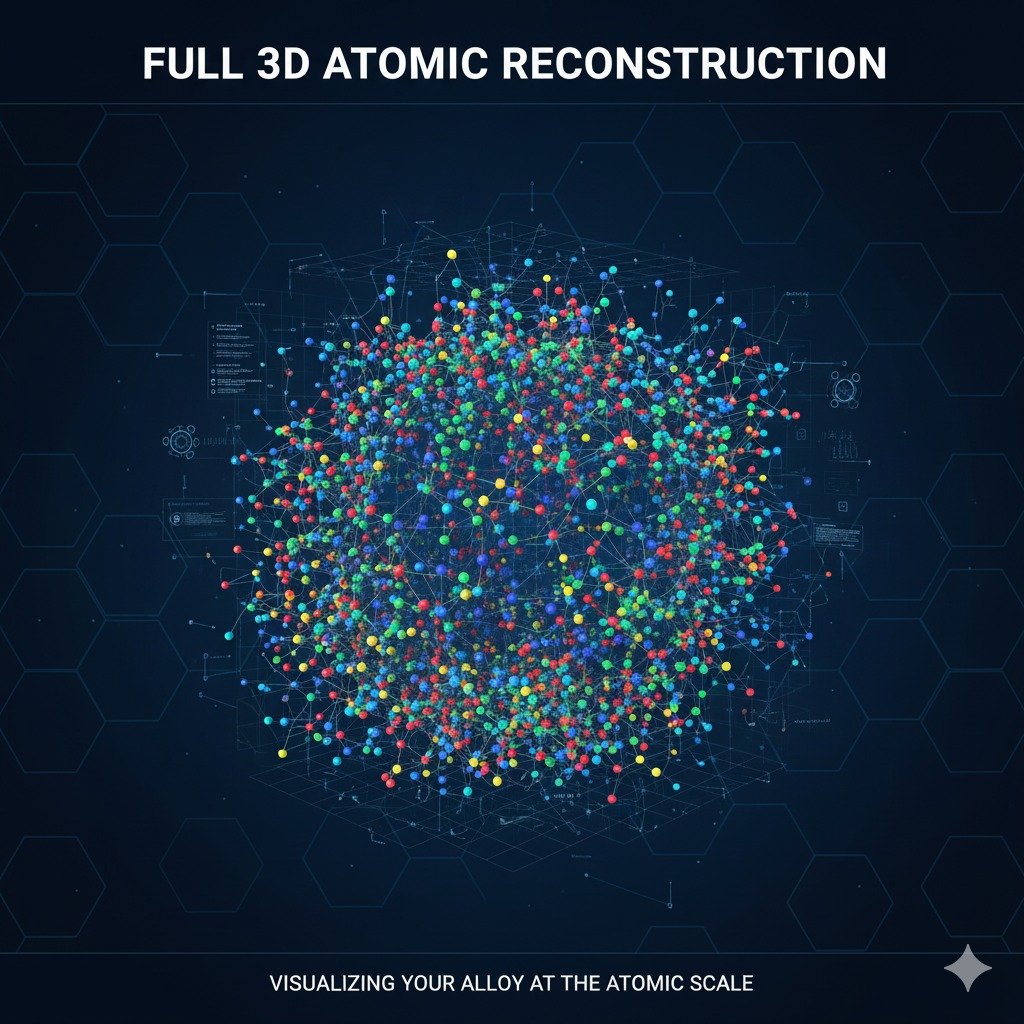

3D atom-probe + AI-driven CALPHAD: we see every solute, design every interface, and prove it in real turbines and EVs.

From creep-proof Ni-blades to recyclable Cu-connectors for electrification—every alloy leaves the lab ready for circular economy.

100+ papers, 2,500+ citations, 10+ alumni now leading labs and startups. Join 50+ global partners who already

To provide advanced capabilities for the characterization of materials and facilitate the training and development of a highly skilled workforce equipped with expertise in materials science.

To enable world class research and foster collaborative partnerships between academia, industry, and government agencies for national needs.

Offering solutions and collaboration to national R&D laboratories and industry, supported by a core group of experts. Also facilitating interaction with faculty and students.

Our services empower brands with innovative strategies and solutions for sustainable growth and engagement.

Every alloy backed by 3D atomic structural study & 100+ citations

SERB/DST/PMRF slots open—zero tuition for stars

Open data, open code, zero green-washing

Delivered an engaging talk on Complex Concentrated Alloys.

- Karthick

Presented on Structure–Property Correlation in Ni-Co Based Alloys.

- Dr. Akshat

We analyze recycled scrap via 3D atom-probe to map impurities and phases. AI-CALPHAD then predicts optimal elemental additions to restore or exceed virgin alloy performance — achieving up to 85% lower CO₂ and 2× component life, proven in turbine blades and EV structures.

Chairing the technical session with insightful discussions.

- Prof. Surendra